Mechanical part of the car. Building a car for beginners.

Today almost everyone drives a car, but not everyone is familiar with the structure of the car. If you want to know how your car works, then you have definitely visited the right site. From this article you can glean enough information to general outline know what components and assemblies your machine consists of. Currently, there are a huge number of brands and models of cars, but almost all passenger cars are designed the same.

Car device diagram

A passenger car consists of the following parts:

- body (supporting structure);

- chassis;

- transmission;

- internal combustion engine (gasoline or diesel);

- engine control system and electrical equipment.

At first glance, everything is simple, but this is only the general structure of the car. For each of the above points, you can write not just an article, but an entire book. But we will not go so deep and will describe only the main points that every driver is simply obliged to know, regardless of driving experience. It should be noted that a simple lack of knowledge about the basic structure of a car is fraught with significant expenses for servicing and repairing the car at a car service center.

Car body

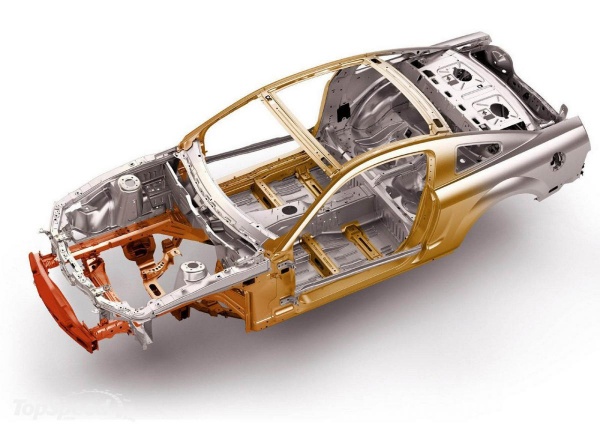

Body passenger car is the load-bearing part to which almost all components and assemblies are attached. Not many people know that the first cars did not have a body, and all components were attached to the frame, like trucks or motorcycles. But in the race to reduce the weight of the car, manufacturers abandoned the frame structure, and a modern body appeared, which in fact is a kind of frame.

Since you and I are studying the structure of a car for beginners, we will look a little more in detail at what the body consists of:

stamped bottom, to which all kinds of reinforcement elements are welded;

- spars (front and rear);

- car roof;

- engine compartment;

- other attachments.

Since the body is a kind of spatial structure, this division is very arbitrary, because all the parts are interconnected. The spars are usually integral with the bottom or welded to it and serve as support for the suspension. Attachable components include fenders, trunk lid, hood and doors. The rear fenders are often welded to the body, and the front fenders can be removable.

Chassis

The chassis consists of many units and components with the help of which the car itself is able to move. Well, since this article describes the design of a car for dummies, so to speak, let’s take a closer look at such a broad concept as “chassis.” The main components of almost any chassis:

suspension (front and rear);

- drive axles;

- wheels.

Most modern passenger cars are equipped with front independent suspension of the MacPherson type. This type of suspension can significantly improve vehicle handling and comfort. In an independent suspension, each wheel is attached to the body using the actual mounting system. Dependent suspension has long been outdated, but is still present on many cars. The rear dependent suspension can be a rigid beam or a live axle, in the case of a rear-wheel drive car.

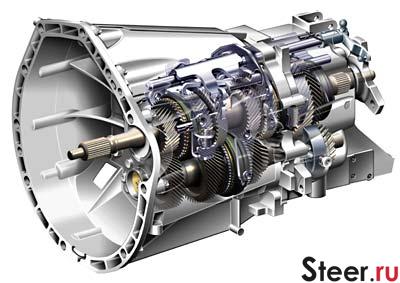

Transmission

The next point in our description of a car for beginners will be the transmission, the main purpose of which is to transmit torque from the engine shaft to the wheels of the car. The transmission consists of the following components:

The next point in our description of a car for beginners will be the transmission, the main purpose of which is to transmit torque from the engine shaft to the wheels of the car. The transmission consists of the following components:

clutch;

- gearbox (gearbox);

- drive axle(s);

- constant velocity joints or cardan transmission.

A car's clutch is designed to connect the engine shaft to the gearbox shaft and is designed to ensure smooth transmission of torque. A gearbox is necessary to change the gear ratio and reduce the load on the car's engine. The drive axle is mounted in the gearbox housing (front-wheel drive) or serves as a rear beam (rear-wheel drive). A cardan drive or CV joints connect the gearbox to the drive axle or directly to the wheels of the car.

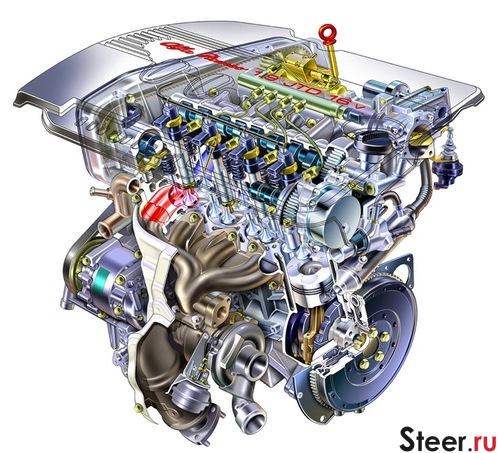

Engine

The purpose of the engine is probably known to everyone, so in our guide to building a car for dummies we will not describe this unit in such detail. The main purpose of the engine is to convert the thermal energy of burned fuel into mechanical energy, which is transmitted to the wheels of the car through the transmission.

The purpose of the engine is probably known to everyone, so in our guide to building a car for dummies we will not describe this unit in such detail. The main purpose of the engine is to convert the thermal energy of burned fuel into mechanical energy, which is transmitted to the wheels of the car through the transmission.

Electrical equipment

The electrical equipment of the car includes the following main components:

rechargeable battery (AB);

- alternator;

- wiring;

- engine control system;

- electricity consumers.

The battery is a constant renewable source of energy and is designed to start the engine. If the engine is not running, the battery supplies electricity to all consumers of the vehicle. The generator serves to maintain constant voltage in the on-board network and recharge the battery. Electrical wiring consists of many wires that form the vehicle’s on-board network, connecting all sources and consumers of electricity. The engine control system consists of an electronic control unit (ECU) and various sensors. Consumers include headlights, taillights, ignition and engine starting systems, windshield wipers, power windows, etc.

As you can see, the car consists of huge amount parts, components and assemblies, but upon closer examination everything is much simpler than it seems at first glance. It is worth noting that this is only a general overview of the design of a passenger car, with the help of which it is simply impossible to cover a description of the design features of specific brands and models.

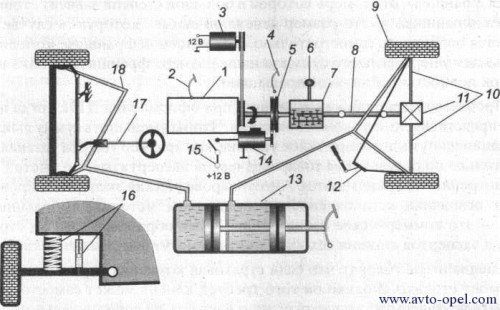

General structure and principle of operation of a passenger car according to the block diagram

The composition and operating principle of modern passenger cars, front-wheel drive, rear-wheel drive and all-wheel drive, are generally the same.

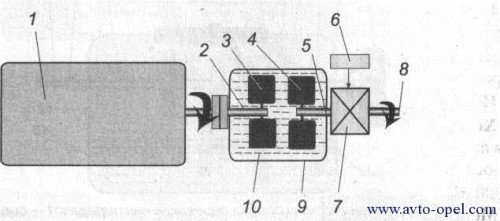

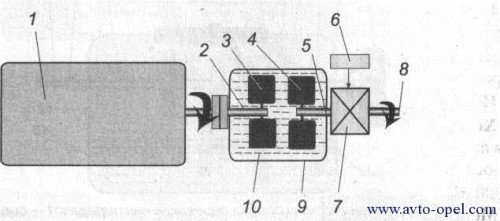

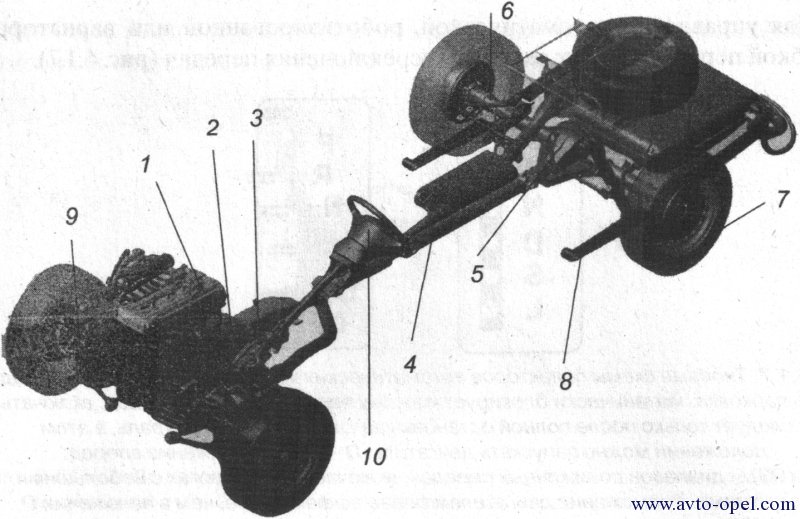

The block diagram of a rear-wheel drive car is shown in Fig. 6.1.1.

The car includes:

- engine 1;

- power train or transmission, which includes: clutch 5, gearbox 7, cardan transmission 8, main gear and differential 11, axle shafts 10;

Rice. 6.1.1. Block diagram of a rear-wheel drive car: 1 - engine; 2 - fuel pedal; 3 - generator; 4 - clutch pedal; 5 - clutch; 6 - gear shift lever; 7 - gearbox; 8 - cardan transmission; 9 - wheel; 10 - axle shafts; 11 - main gear and differential; 12 - parking (hand) brake; 13 - main brake system; 14 - starter; 15 - power supply from battery; 16 - suspension; 17 - steering; 18 - hydraulic main

- chassis, which includes: front and rear suspension 16, wheels and tires 9;

- governance mechanisms, consisting of a steering 17, a main 13 and a parking 12 brake system;

- electrical equipment, which includes sources electric current(battery and generator), electrical consumers (ignition system, starting system, lighting and alarm devices, instrumentation, heating and ventilation systems, windshield wiper, windshield washer, etc.);

- monocoque body.

Front-wheel drive cars do not have a driveshaft or driveshaft box in the body, so the interior becomes more spacious and comfortable, and the vehicle weighs less.

Engine 1 (Fig. 6.1.1) - a machine that converts any type of energy (gasoline, gas, diesel fuel, electrical charge) into rotational energy of a cranked engine.

Most modern cars are equipped with piston internal combustion engines (ICE), in which part of the energy released during the combustion of fuel in the cylinder is converted into mechanical work rotation of the crankshaft (Fig. 6.1.2).

Displacement is a unit of measurement of engine volume equal to the product of the piston area by the length of its stroke and the number of cylinders. Displacement characterizes the power and size of the engine, expressed in liters or cubic centimeters.

To change the amount of fuel mixture supplied to the cylinder (to change engine power), use the fuel pedal (gas pedal) 2.

Rice. 6.1.2. Appearance modern engine: 1 - valve box cover; 2 - neck plug for filling oil into the engine; 3 - cylinder head; 4 - pulleys; 5 - drive belt; 6 - generator; 7 - crankcase; 8 - pallet; 9 - exhaust manifold

A flywheel with a toothed ring is installed on the crankshaft, which is the drive clutch disc 5.

Clutch 5 provides a permanent mechanical connection between the engine and the gearbox and is designed to temporarily disable it for the time required to engage or shift gears.

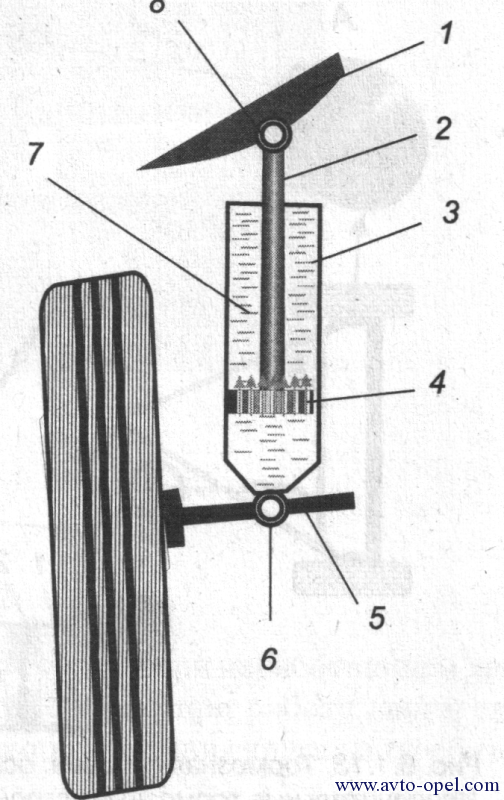

The clutch (Fig. 6.1.3) consists of two friction clutches 1 and 3, pressed against each other by a spring 4. Drive disk 1 is mechanically connected to the engine crankshaft, driven disk 3 is connected to the drive shaft of the gearbox 14.

The clutch is turned on and off by the driver using pedal 8 (when the pedal is pressed, the clutch is disengaged). When you press the pedal, clutch discs 1 and 3 diverge, drive disc 1, connected to engine 13, rotates, but this rotation is not transmitted to driven disc 3 (the clutch is disengaged). The clutch must be disengaged during the period of engaging or shifting gears to ensure a shock-free connection of the gears in the gearbox.

When the pedal is smoothly released, the driving and driven disks engage smoothly. At the same time, due to slipping, the driving disk smoothly imposes rotation on the driven disk. It begins to rotate, transmitting torque to the input shaft of gearbox 14. Thus, the car can start moving smoothly from a standstill or continue moving in a new gear.

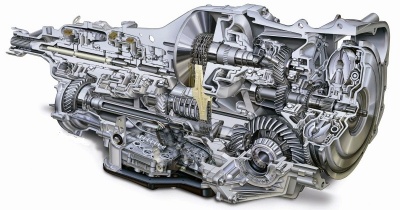

The gearbox serves to change the magnitude and direction of torque and transmit it from the engine to the drive wheels, as well as for long-term disconnection of the engine from the drive wheels while the vehicle is parked.

The gearbox can be mechanical (with manual gear shift) or automatic (torque converter, robotic or CVT).

Rice. 6.1.3. Clutch diagram: 1 - flywheel; 2 - clutch driven disc; 3 - pressure disk; 4 - spring; 5 - release levers; 6 - release bearing; 7 - clutch release fork; 8 - clutch pedal; 9 - clutch master cylinder; 10 - hydraulic fluid; 11 - pipeline; 12 - clutch slave cylinder; 13 - engine; 14 - gearbox drive shaft; 15 - gearbox

Manual gearbox (Fig. 6.1.4) is a gearbox with a stepwise variable gear ratio.

It contains:

- crankcase 12, which contains oil 13 for lubricating rubbing parts;

- input shaft 2 connected to clutch driven disc 1

- input shaft gear 3, which is permanently connected to the intermediate shaft gear;

- intermediate shaft 4 with a set of gears of different diameters;

- a secondary shaft 9 with a set of gears that can be moved using the gear shift fork 6;

- gear shift mechanism 8 with shift lever 7;

- synchronizers are devices that ensure equalization of gear rotation speeds during gear shifts.

The driver changes gears using shift lever 7. Since the gearbox of a modern car has a large set of gears, by engaging different pairs of them (when engaging any gear), the driver also changes the overall gear ratio (gear ratio). The lower the gear, the lower the vehicle speed, but the greater the torque and vice versa.

When the engine is running, before turning on or shifting gears in a manual transmission, in order to shift gears without shock, you need to depress the clutch pedal (disengage the clutch).

Rice. 6.1.4. Manual gearbox: 1 - clutch; 2 - input shaft; 3 - drive gear; 4 - intermediate shaft; 5 - secondary shaft gear; 6 - gear shift fork; 7 - gear shift lever; 8 - switching device; 9 - secondary shaft; 10 - cross; 11 - cardan transmission; 12 - crankcase; 13 - gearbox oil

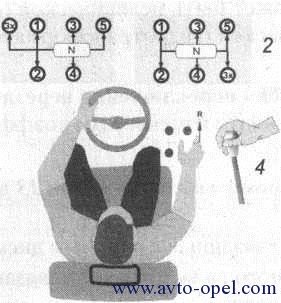

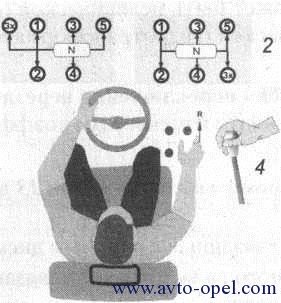

The most common gear shift patterns in passenger cars are shown in Fig. 6.1.5.

Rice. 6.1.5. The most common gear shift patterns in passenger cars are 1 and 2, 3 and 4 - using the gear lever

In automatic gearbox(Fig. 6.1.6) includes:

- The torque converter (2, 5, 4, 5, 9), which is directly connected to the engine, is filled with hydraulic fluid 10. The fluid is the medium for transmitting torque from the engine to the manual transmission. The principle of operation is as follows: with increasing engine speed, the revolutions of shaft 2 with blades 3 increase, which cause rotation of the hydraulic fluid 10. The rotating fluid begins to put pressure on the blades of the secondary shaft 4 and causes rotation of the secondary shaft. The torque converter essentially acts as a clutch;

- The manual gearbox 7 receives rotation from the torque converter, gear shifting in it is carried out by servo drives according to commands from the control unit 6.

Rice. 6.1.6. Automatic gearbox: 1 - engine; 2 - input shaft; 3 - blades of the input shaft; 4 - secondary shaft blades: 5 - secondary shaft; 6 - automatic transmission control unit; 7 - manual gearbox; 8 - output shaft

To control an automatic, robotic or CVT transmission, use the gear selector (Fig. 6.1.7).

Rice. 6.1.7. Typical diagrams of automatic gearbox selectors:

P - parking, mechanically blocks the gearbox; R- reverse, should only be turned on after the vehicle has come to a complete stop; N - neutral, in this position you can start the engine; D - drive, forward movement; S (D3) - low gear range, activated on roads with slight inclines. Engine braking is more effective than in position D; L (D2) - second range of low gears. Turns on on difficult road sections. Engine braking is even more effective

Cardan transmission(in rear- and all-wheel drive vehicles) allows you to transfer torque from the gearbox to the rear axle (main gear) when the vehicle is moving on a rough road (Fig. 6.1.8).

Rice. 6.1.8. Cardan transmission: 1 - front shaft; 2 - cross; 3 - support; 4 - cardan shaft; 5 - rear shaft

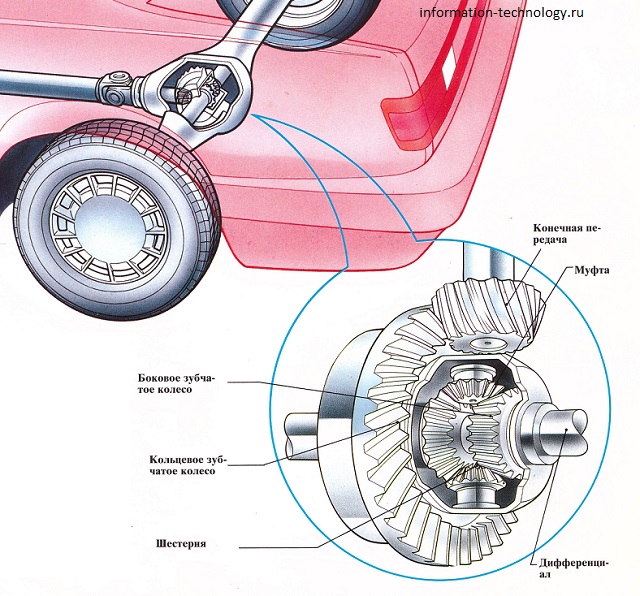

main gear 5 serves to increase torque and transmit it at right angles to axle shaft 6 of the vehicle (Fig. 6.1.9).

Differential ensures rotation of the drive wheels at different speeds when the car turns and the wheels move on uneven roads.

Half shafts 6 transmit torque to the drive wheels 7.

Chassis ensures movement and smoothness. It includes a subframe, usually combined with the car body, to which elements of the front and rear axles with hubs and wheels 7 are attached through the front and rear suspensions.

Mechanisms and parts of the chassis connect the wheels to the body, dampen its vibrations, perceive and transmit forces acting on the car.

While inside a passenger car, the driver and passengers experience slow vibrations with large amplitudes and fast vibrations with small amplitudes. Soft seat upholstery, rubber engine mounts, gearboxes, etc. protect against fast vibrations. Elastic suspension elements, wheels and tires protect against slow vibrations.

Rice. 6.1.9. Rear-wheel drive car: 1 - engine; 2 - clutch; 3 - gearbox; 4 - cardan transmission; 5 - main gear; 6 - axle shaft; 7 - wheel; 8 - spring suspension; 9 - spring suspension; 10 - steering

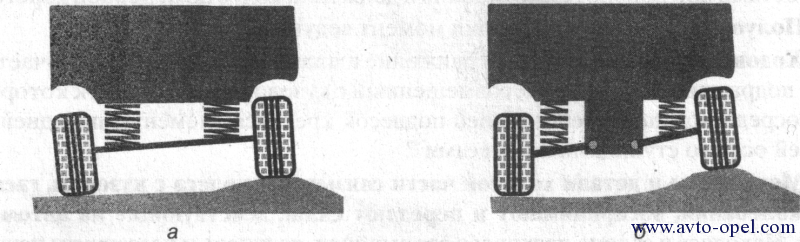

The suspension (Fig. 6.1.10) is designed to soften and dampen vibrations transmitted from road irregularities to the car body. Thanks to the wheel suspension, the body makes vertical, longitudinal, angular and transverse angular vibrations. All these vibrations determine the smoothness of the car. The suspension can be dependent or independent.

Dependent suspension (Fig. 6.1.10), when both wheels of one vehicle axle are connected to each other by a rigid beam (rear wheels). When one of the wheels hits an uneven road, the other one tilts at the same angle. Independent suspension, when the wheels of one axle of the car are not rigidly connected to each other. When hitting an uneven road, one of the wheels may change its position, but the position of the second wheel does not change.

Rice. 6.1.10. Diagram of operation of dependent (a) and independent (b) car wheel suspension

An elastic suspension element (spring or spring) serves to soften shocks and vibrations transmitted from the road to the body.

Rice. 6.1.11. Shock absorber diagram:

1 - car body; 2 - rod; 3 - cylinder; 4 - piston with valves; 5 - lever; 6 - lower eye; 7 - hydraulic fluid; 8 - upper eye

The damping element of the suspension - the shock absorber (Fig. 6.1.11) - is necessary to dampen body vibrations due to the resistance that occurs when fluid 7 flows through calibrated holes from cavity “A” to cavity “B” and back (hydraulic shock absorber). Gas shock absorbers can also be used, in which resistance occurs when gas is compressed. A vehicle's anti-roll bar is designed to improve handling and reduce vehicle roll when cornering. When turning, the car body presses one side of it to the ground, while the other side wants to go “away” from the ground. It’s the anti-roll bar, which, pressing one end to the ground, presses the other side of the car with the other, preventing him from getting away. And when a wheel hits an obstacle, the stabilizer rod twists and tries to return this wheel to its place.

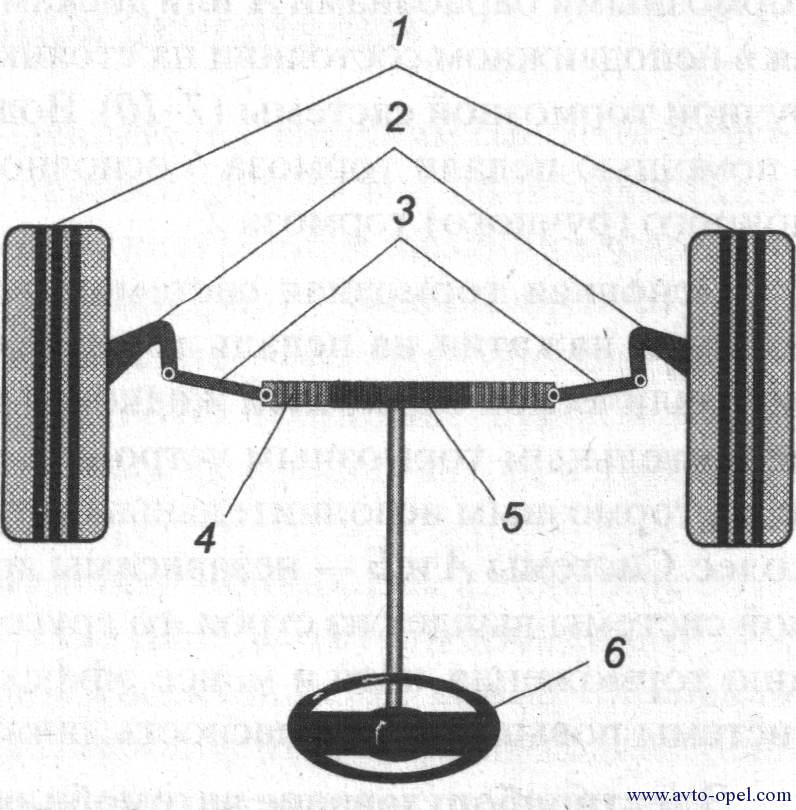

Rice. 6.1.12. Steering diagram of the “gear-rack” type: 1 - wheels; 2 - rotary levers; 3 - steering rods; 4 - steering rack; 5- gear; 6-wheel steering

Steering(Fig. 6.1.12) serves to change the direction of movement of the car using the steering wheel. When the steering wheel 6 rotates, the gear 5 rotates and moves the rack 4 in one direction or another. When moving, the rack changes the position of the rods 3 and the associated rotary levers 2. The wheels turn.

Rice. 6.1.13. Brake system: main - 1-6 and parking (manual) -7-10. Actuating brake devices: A-disc; B - drum type; 1 - main brake cylinder; 2 - piston; 3 - pipelines; 4 - hydraulic brake fluid; 5 - rod; 6 - brake pedal; 7 - hand brake lever; 8 - cable; 9 - equalizer; 10 - cable

Brake system(Fig. 6.1.13) serves to reduce the speed of rotation of the wheels due to the friction forces arising between the brake pads 11 and brake drums A or discs B, as well as to hold the car stationary in parking lots, on descents and ascents using the hand brake systems (7-10). The driver controls the brake system using the brake pedal 6 of the main brake system and the parking-night (hand) brake lever 7.

The main brake system (1-6), as a rule, is multi-circuit, that is, when you press the brake pedal 6, the pistons 2 move, the pressure of the hydraulic brake fluid 4 is transmitted through pipelines 3 to the brake actuators A - for braking the front wheels and the brake actuators B - for braking the rear wheels. Systems A and B are independent of each other. If one circuit of the brake system fails, the other will continue to perform the braking function, although less effectively. The multi-circuit braking system increases traffic safety.

Car electrical equipment includes sources of electric current (battery, generator) and electrical consumers (starting, ignition systems, lighting, alarm devices, instrumentation, windshield wipers, windshield washers, heating, ventilation systems, etc.).

The battery energy is used when the engine is not running, the generator energy is generated only when the engine is running, it is used to recharge the battery and power other vehicle consumers.

Body the car is rigid, load-bearing.

The world's first car with a gasoline engine was patented back in 1885 by the brilliant German engineer Karl Benz. Amazingly, even today the car consists of the same main parts as a hundred years ago - the body, chassis and engine. Let's take a closer look at what a car consists of.

It is, of course, difficult to describe the detailed structure of a car in one short article, so we will consider only the basics that every car enthusiast should know.

At the end of this educational material you will find a short video tutorial about the structure of a car, describing the main parts that it consists of and their functions.

It is also worth noting that ignorance of the general structure of the car and the operating principle of its main components and assemblies leads to increased costs for car repairs and maintenance.

General structure of the car

Engine– this is the heart of the car. It is a source of mechanical energy and sets our car in motion. Internal combustion engines are most widespread in the automotive industry. However, in last years Cars equipped with electric and hybrid engines are becoming increasingly popular.

Car chassis deserves special attention. It consists of many mechanisms whose tasks include transmitting torque from the power unit (engine) to the drive wheels, moving the car and controlling it. These groups of mechanisms are called transmission, chassis and vehicle control mechanism.

- Car transmission serves to transmit torque from the engine to the drive wheels, thereby allowing the torque to be changed in magnitude and direction. The transmission of a two-axle car with a front engine and rear-wheel drive usually consists of the following mechanisms: clutch, gearbox, driveline, final drive, differential and axle shafts.

- Car chassis consists of a frame or supporting body, front and rear axles, suspension (springs and shock absorbers), wheels and tires. Read more about the types and types of car suspensions.

- Car control mechanism consists of steering and braking system (drum brake and disc brakes). It allows you to change the direction and speed of the car, stop it and hold it in place.

In addition to the above components, assemblies and mechanisms, absolutely all cars are equipped with electrical equipment, consisting of sources and consumers of electric current.

Car electrical equipment starts and allows the engine to work, illuminates and heats the interior of the car, allows you to move without problems in the dark and in bad weather, supports the anti-theft system, takes care of our safety on the road, turns the car into a concert hall or even a cinema, and performs many other useful and very important functions.

Video lesson: what a car consists of

The first production car was built at the beginning of the 20th century at the Ford plant. The first car was assembled in 1908. It was a Ford Model T. The car was produced until 1928 and became a legend.

The brilliant manager and mechanic Henry Ford always said: “A car can be any color as long as it is black.” He placed the main emphasis on the versatility of the car, completely rejecting individuality. This is what destroyed him.

Despite the versatility of the Ford Model T and its simple but reliable functionality, in the 20s it had a competitor in the form of General Motors cars. This company offered each buyer a unique car with an unusual internal structure.

In those days there were only manual gearboxes and weak engines. Car speeds rarely exceeded 50 miles per hour. Now everything has changed. Modern cars are masterpieces of engineering, the insides of which are filled with the most advanced electronics and highly complex control systems.

Technical parameters have long gone beyond the scope of science fiction. Now acceleration to 100 kilometers in 4 seconds is a reality that will not surprise anyone. At the same time, there are hundreds of companies on the market that sell a wide variety of cars. Nevertheless, despite all this diversity, the general design of their cars is very similar.

What does a car consist of?

Of course, the design of a modern machine includes many different components and parts, but even among them the main ones can be identified:

- transmission,

- body,

- chassis,

- control systems,

- electrical equipment.

Each of these elements plays an important role that is difficult to overestimate. To understand how important the correct operation of each part is, let's look at them in more detail.

Body

The body is the supporting part of the car. It is to it that all components and assemblies are attached. Nowadays, automobile manufacturers are trying to do everything possible to select the most durable and lightest composite resin that will serve as the basis of the product.

The fact is, ordinary metal weighs quite a lot. Weight gain negatively affects the dynamics, maximum speed and acceleration, and driving a heavy car is very difficult. As a result, non-standard approaches to creating bodies are now increasingly being used. For example, hydrocarbon fiber is used in construction.

Perhaps the most striking car where this technology was used was the Lykan Hypersport. You might have seen this car in the movie "Fast and Furious 7". The use of carbon fiber to create the body made it possible to greatly lighten the car, significantly increasing all its characteristics. By the way, The cost of the car is more than three million.

In fact, the body is the frame that holds the entire structure of the car together. At the same time, it must have sufficient rigidity to withstand truly heavy loads. At speeds of more than 200 kilometers per hour, the driver’s life depends on its strength.

The body used in the construction of the car must not only be light and durable, but also have the correct aerodynamic shape. Speed and control depend on how effectively the machine body cuts air flows.

Traditionally, the body, which is part of the vehicle structure, can be divided into the following elements:

- spars,

- roof,

- brakes,

- hanging parts,

- engine compartment,

- bottom.

In order to achieve greater rigidity, reinforcing elements are welded to the underbody structure of the car. They provide increased strength and greater safety of the entire structure.

Each of these elements is connected to each other. So the spars are one solid structure together with the bottom. In some cases they are welded to it. The main task of these parts in a car is to create support for the suspension.

If we talk about attached parts, then the wings immediately come to mind. You also can’t ignore the trunk, doors and hood. They are attached parts, but are very closely connected to the car body.

Attention! To achieve greater structural stability, the rear fenders are welded to the body, and the front fenders are made removable.

Such nuances need to be taken into account if you want to tune your iron horse. Moreover, precisely to Modification parts are attached to the body parts. Suffice it to recall the same spoiler. Even neon inserts are mounted around the perimeter of the bottom.

Tuning the body gives the greatest visual effect. In addition, additional elements, such as a low-slung bumper, can provide the design with much better aerodynamic qualities.

Without a chassis

The chassis plays the role of a foundation in a car. It is thanks to this that the car can move. For example, wheels, suspension and axles are all its elements. Without them, the movement itself would be impossible.

The system can have both front independent suspension and rear dependent suspension. Nowadays, most cars use the first option, as it gives the best controllability of the vehicle.

The main difference between an independent suspension is that each wheel is mounted separately. Moreover, in the structure of the car, all wheels have their own fastening systems.

Dependent suspension is considered a kind of archaism in automotive circles. Nevertheless, some companies still use it in order to save money and simplify the design of the car as much as possible. Nevertheless, it ensures high reliability of the design. Moreover, the tricks of some manufacturers make it possible to achieve truly outstanding results using this outdated technology.

I would like to remember the same German concern BMW. This company has been producing cars for many years that feature rear dependent suspension.

Nevertheless, rear-wheel drive cars of the German brand are famous all over the world. Moreover, many drivers buy these cars with a rear suspension device precisely because of the pleasure that the driver receives while sitting behind the wheel of this monster.

Attention! Rear-wheel drive makes it possible to feel the real pleasure of driving a powerful, fast and predatory car.

Typically the rear suspension is a live axle. In some cases, machine builders install a rigid beam, and this is quite enough to ensure optimal structural strength.

Brakes

If the previous part contained the car itself and its entire structure, then the role of the braking system is completely different. Reliable brakes can prevent many accidents and save millions of lives.

Many automotive experts do not consider it necessary to highlight this element in the car. They just consider it part of the chassis. However, this is fundamentally wrong. After all, the importance of brakes in modern heavy traffic can hardly be overestimated.

Nowadays, three elements of the brake structure are most often distinguished:

- Working - allows you to control the speed. This subsystem is responsible for gradually reducing speed until the vehicle comes to a complete stop.

- Spare - it is needed when the main system in the car fails. Usually it is made completely autonomous.

- The parking brake is a handbrake that holds the car in one place while you are away.

In modern brake systems Many additional devices are used that provide better job brakes Of particular importance are a variety of amplifiers and anti-lock braking systems. These elements make it possible not only to increase the efficiency of the system several times, but also to increase its comfort for the driver.

Transmission

This device transmits torque from the shaft to the wheels. The structure consists of the following elements:

- clutch,

- hinges,

- gearboxes,

- drive axle.

Thanks to the clutch, designers in the car establish a connection between the engine shafts and the gearbox. In turn, the gearbox greatly reduces the load on the engine, increasing its service life and ensuring the most efficient fuel consumption.

It is worth recognizing that in recent years many options for gearbox design have been invented. The first was a manual transmission. It was invented at the beginning of the twentieth century. The first car on which it was installed was still the same legendary model American company"Ford" - T.

About 40 years have passed since then, and in the 50s the automatic transmission was invented. Now it is not the driver who decides when to engage a new gear, but the hydraulic system. The advantage of such a device is its simplicity and smooth switching.

Finally, the third round of evolution of the gearbox device is the robot. This box combines all the advantages of a manual and automatic transmission. The thing is that a smart program switches gears. It determines the required time to within a few tenths of a millisecond and carries out the transition. As a result, the driver receives enormous fuel savings.

Important! There is also a CVT, but it is rarely used.

Engine

Perhaps this is the most important part of the car - its heart. The speed and dynamics of the machine depend to the greatest extent on the power of this device. The essence of the operating principle of this part is extremely simple. The engine converts thermal energy into electrical energy by burning fuel.

Electrical equipment and control systems

The fact is that every year these complexes of car devices are becoming more and more connected with each other. Smart systems manage wiring voltage, battery operation and power consumption. This approach turns cars into thinking devices that decide where the driver is best to park and monitor cars driving nearby.

Results

The device of a car is a complex system, which takes years to study. Nevertheless, even a beginner can study and understand the general scheme and purpose of all nodes. This knowledge can help both on the road and in car maintenance.

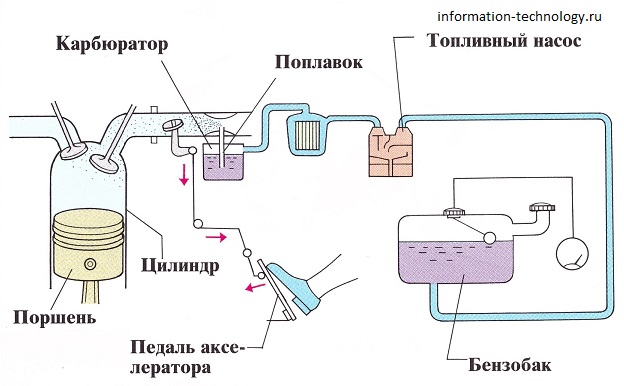

A car can be defined as follows: it is a mechanical device that releases the latent energy of gasoline and, by controlling the released energy, uses it to rotate the wheels. Gasoline fuel is injected into each of the engine cylinders in turn (picture above), and there it burns. The energy released during combustion moves the piston of the cylinder. The piston goes down the cylinder like a fist when we put our hand into the sleeve, and through the crankshaft, using the clutch mechanism, transmits energy to the gearbox.

After the gearbox, the energy of rotational motion is transferred to the drive shaft. It rotates together with the differential mechanism. And the differential not only transfers power to the drive axles, mounted perpendicular to the drive shaft, but also allows the left and right wheels to rotate at different speeds, if necessary. For example, when a car is moving around a bend.

The operating cycle of an internal combustion engine

During fuel intake, the piston goes down and a mixture of gasoline vapor and air is drawn into the cylinder. Then the piston rises - the mixture is compressed. A spark appears on the spark plug - the fuel mixture ignites and burns - and the energy released during combustion forces the piston to go down. In the last, fourth stroke of movement, the piston rises again and pushes the exhaust gases through the exhaust valve.

Formation of a flammable mixture

Ignition circuit

The accelerator helps the carburetor prepare the currently required amount of fuel mixture, which consists of gasoline vapor and air. This mixture is then drawn into the cylinders and ignited there using spark plugs

Mechanism for controlling two unequal movements

In order for a car to corner smoothly, its wheels on the outside of the track must move faster and travel a greater distance than the wheels on the inside of the track. This is possible thanks to the presence of a mechanism in the car called a differential. It is an intricate set of mechanical gears with gears and gears that connect the drive shaft to the rear wheel axles so that each wheel can rotate at the speed it needs.